If you are a brake pad consumer, you may only care about how to replace brake pads. However, for a brake pad importer, distributor or buyer, they are more care about how the brake pads are manufactured and what the most important process for a brake pad is in manufacturing.

The post below can help you to learn basic procedures how brake pad are manufactured.

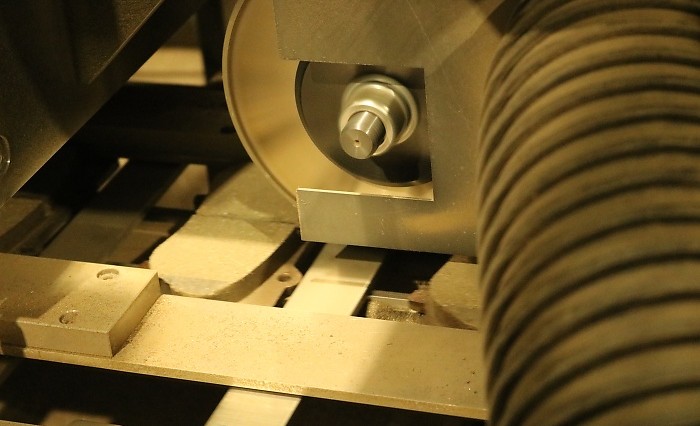

1, Raw friction material

Friction material is the most important for a brake pad. The different factories have their own formula.The formula determines the quality of the products. According to the classification, there are mainly 4 kinds of formulas. Metallic, semi-metallic, ceremic, NAO disc pad formula.(Click here to learn more about disadvantage and advantage of different brake pad formula)